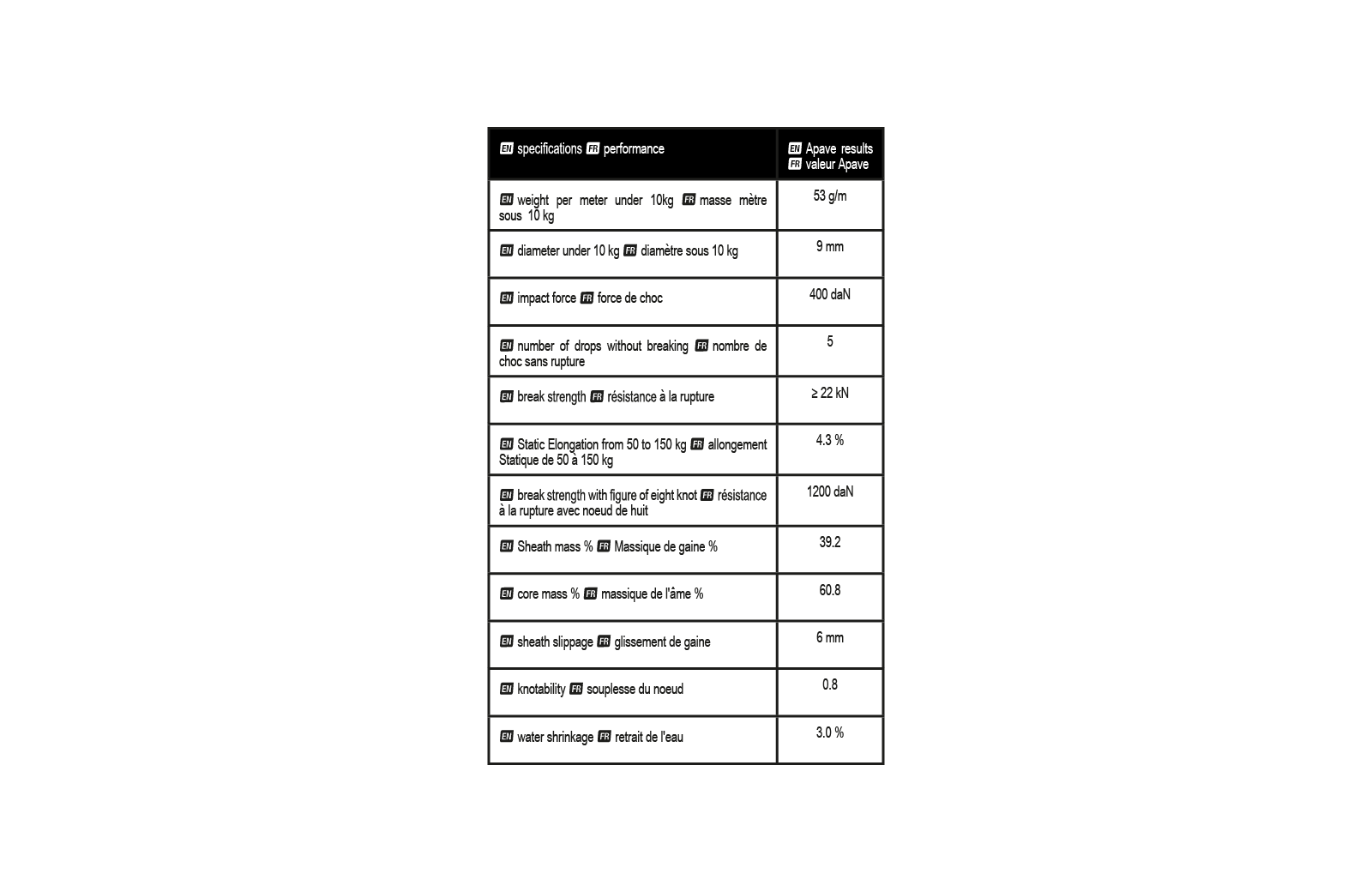

- This product is a static rope intended for caving, canyoning, ropework or work at height, rescue or safety operations. Its use must allow the movement, progress or descent of a person in accordance with the conditions set out below.

- If the user is practising free climbing, he/she must use a dynamic rope that complies with standard EN 892. Static ropes should never be used if the user could find him/herself in a position where they could suffer a fall above factor 1. For optimum safety, a reliable anchor point above the user is required, as well as avoiding ropes becoming improperly tensioned between the user and the anchor point.

- The user, in a normal situation or in an emergency, must be in perfect medical condition, physically and mentally, in order to use this static rope safely.

- This product must be used by trained and/or competent people or the user must be supervised by a trained and/or competent person.

- In order to prepare for any eventuality, before using this rope, a rescue plan must be drawn up and implemented if necessary. This product must in no case be modified or added to any other product without the prior agreement of the manufacturer, and any repair must be in accordance with the manufacturer’s operating instructions.

- This rope is designed to withstand the static forces involved in activities where there is a risk of falling from a height.

- The equipment must not be used beyond its limits or in any situation other than those mentioned above.

- The rope is personal equipment. It may suffer unseen damage in your absence. For better surveillance, when the rope is

used by a group, we recommend that you appoint a user or responsible person for each product.

- Thin ropes may require a specific belay device.

The overlap of two ropes in the same carabiner or link can cause the rope(s) to break. Descending too quickly and top-roping are to be avoided, as they cause premature wear and can burn the rope. The maximum permis- sible operating temperature is 80°C for a short time. Before abseiling or top-roping, check the length of the rope. As an extra precaution, tie a knot at the end of the rope.

- Before and after each outing, carry out a visual and physical inspection of the rope to check its general condition. If in doubt, return the rope to the manufacturer.

- The user should consider the rope to be defective if there are traces of burns to the sheath, if the rope is nicked, if its diameter is irregular, if there are localised abrasions or traces of internal wear, noticeable lengthening compared to the original length or if it shows any other signs of deterioration.Visual and manual inspection is therefore required before each use. Take all the necessary safety precautions.

- If there is any doubt about the safety of the equipment or if it has already been used to stop a fall and should not be used until a competent person has authorised its reuse in writing, the rope must be taken out of use.

-The minimum resistance of the anchoring device or chosen structure must be at least 15kN.

- Use a carabiner or quick link for abseiling and top-roping. The relay must consist of at least two independent anchor points. The various belaying components (harnesses, carabiners, straps, descenders, anchor points) must be chosen in accordance with European and/or EC-approved standards and be used with full knowledge of their limits of use in progression and in safety systems. They must also be adapted to the diameter of the rope.

- Beware of the danger of using multiple items for which the safety feature of one item is affected by the safety feature of another item interfering with it.

- The figure-eight knot is recommended for roping in.Make a really tight figure-eight knot. The minimum length of rope that must pass beyond the knot is 10 cm.On a fall arrest harness, use the tie-in points specified by the manufacturer.

- To minimise the risk of falling and the height of any fall: under no circumstances must the anchor point from the rope to the relay be positioned below the user, so as not to exceed Fall Factor 1.

- The fall arrest harness (compliant with EN361) is the only device for holding the body allowed in a fall arrest system (as per EN 363).

- Before and after use, the possible height of falls must be anticipated. The user must position him/herself in relation to his/her relay so as never to be above it. Always check the free space below the user (according to the instructions in each manual for the associated equipment) to avoid any collision

with an obstacle.

- The rope must not come into contact with corrosive and ag- gressive materials or chemical agents (acids, oils, petrol) which can destroy the fibers without being visible.

- During transport, a rope bag that protects the rope from dirt and reduces the risk of fraying is highly recommended.